Tube Laser Cutting System 6.3.761.9

Monaco high-power Femtosecond Lasers offer exceptional edge quality in micromachining, and improves in scientific applications such three-photon Microscopy.

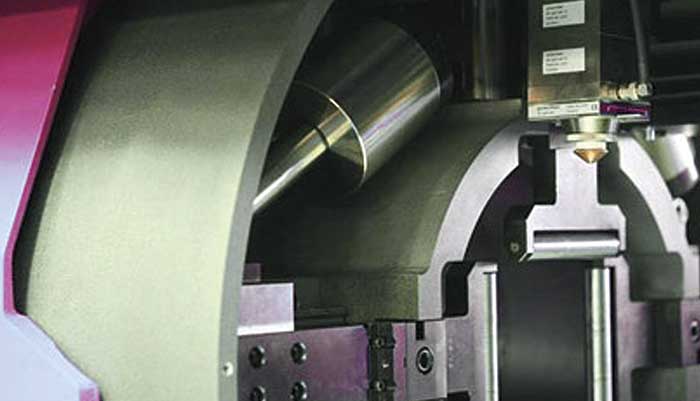

ExactCut 430 allows for precise laser cutting of metals and alloys. It also automates the production of brittle materials like ceramics, sapphire, and PCD.